海水冷卻系統

SEAWATER COOLING SYSTEM

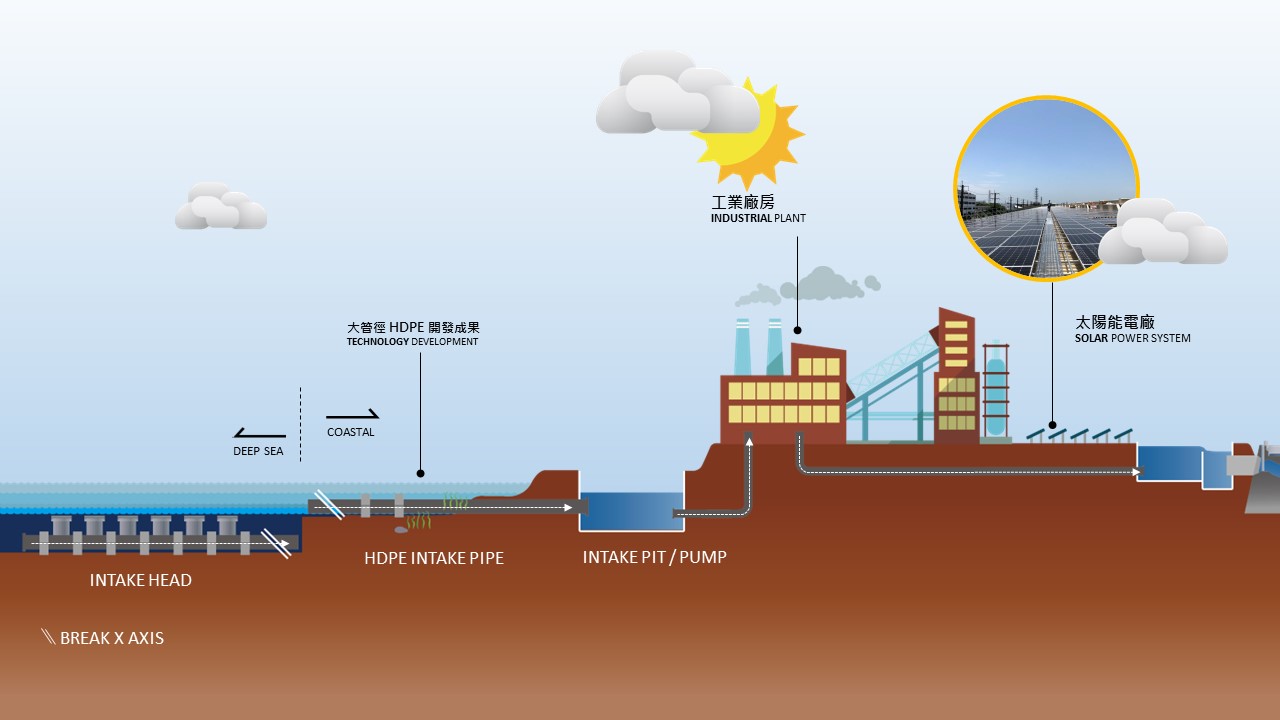

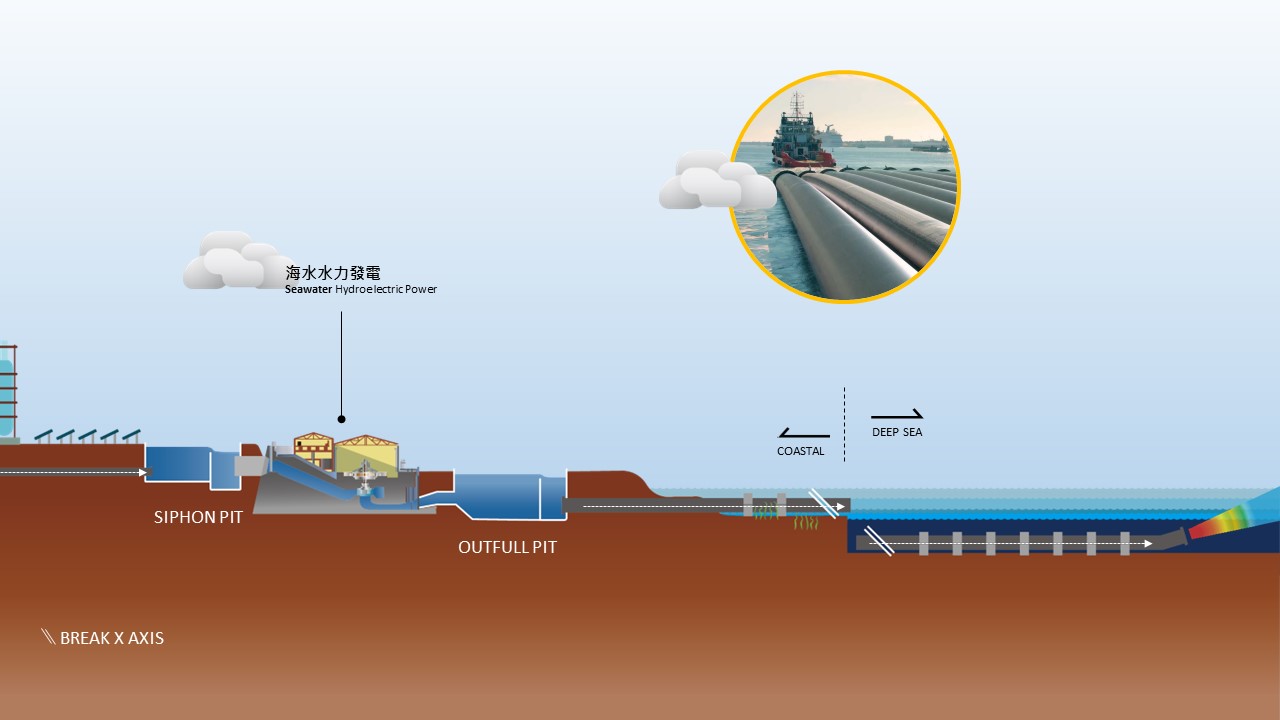

海水冷卻系統的原理是利用海水來降低機械設備或工業過程的溫度,通常在發電廠、化工廠、石化廠等大型工業場所中使用。具體的原理是,通過泵將海水抽到冷卻器中,然後將冷卻器中的熱量轉移給海水,使得冷卻器中的熱量被海水帶走,進而達到降溫的目的。

在冷卻系統中,海水通常是從海洋或者其他水體中抽取的,經過初步的過濾和處理後,再輸送到冷卻塔或冷卻器中,完成冷卻過程。通常情況下,冷卻塔或冷卻器會利用風力或者水力將冷卻水與大氣進行接觸,進而使冷卻水中的熱量散發到大氣中。在一些場合下,冷卻水也可以通過熱交換器,轉移給其他介質,進而實現熱能的回收。

HDPE(高密度聚乙烯)海水冷卻系統是一種新型的海水冷卻系統,它採用HDPE管材,可以防止腐蝕和生物污染,同時具有良好的耐磨性和耐腐蝕性,因此在海水環境中有著廣泛的應用。該系統的特點包括:

- 耐腐蝕性

HDPE 管材可以抵抗海水中的鹽分和酸鹼等腐蝕性物質,並且不容易被腐蝕和生物污染。 - 良好的耐磨性

HDPE 管材可以承受流體中的高速水流,而且具有較好的耐磨性,使用壽命長。 - 輕量化

相對於傳統的金屬管道,HDPE管道的重量更輕,運輸和安裝更加方便。 - 低維護成本

HDPE 管材不需要像金屬管道那樣經常清理和維護,因此維護成本更低。 - 環保節能

相對於傳統的冷卻系統,HDPE海水冷卻系統具有更好的環保節能效果,可以降低能耗和減少二氧化碳排放。

HDPE 海水冷卻系統在設計和安裝時需要根據實際情況進行評估和調整,以確保系統的運行穩定和效果良好。

The principle of a seawater cooling system is to use seawater to lower the temperature of mechanical equipment or industrial processes, typically in large industrial facilities such as power plants, chemical plants, and petrochemical plants. Specifically, seawater is pumped into a cooling unit, where heat is transferred from the unit to the seawater, allowing the seawater to carry away the heat and achieve the cooling effect.

In a cooling system, seawater is usually extracted from the ocean or other bodies of water, undergoes preliminary filtration and treatment, and is then transported to a cooling tower or cooling unit to complete the cooling process. Typically, a cooling tower or cooling unit uses wind or hydraulics to allow the cooling water to come into contact with the atmosphere, thereby dissipating the heat into the atmosphere. In some cases, the cooling water can also be transferred to other media through a heat exchanger, allowing for the recovery of thermal energy.

The HDPE (High-Density Polyethylene) seawater cooling system is a new type of seawater cooling system that uses HDPE piping. It can prevent corrosion and biological contamination, while also having good wear and corrosion resistance, making it widely used in marine environments. The features of this system include:

-

CORROSION RESISTANCE

HDPE pipes can resist corrosive substances such as salt and acid and are less likely to be corroded or contaminated by biological organisms. -

GOOD WEAR RESISTANCE

HDPE pipes can withstand high-speed fluid flow and have good wear resistance, resulting in a long service life. -

LIGHTWEIGHT

HDPE piping is lighter than traditional metal piping, making transportation and installation more convenient. -

LOW MAINTENANCE COSTS

HDPE pipes do not require frequent cleaning and maintenance like metal pipes, resulting in lower maintenance costs. - Environmentally friendly and energy-saving: Compared to traditional cooling systems, HDPE seawater cooling systems have better environmental and energy-saving effects, reducing energy consumption and carbon dioxide emissions.

During the design and installation of HDPE seawater cooling systems, it is necessary to evaluate and adjust according to the actual situation to ensure the stable operation and good performance of the system.

掌握關鍵技術

MASTERING KEY TECHNOLOGIES

我們耕耘亞洲市場多年,亞洲獨家引進 HDPE 海水冷卻系統,擁有 HDPE 海管建置多項技術專利,並持續研究開發大管徑產品,2022 年單管直徑已經達到 3.5M。

We have been cultivating the Asian market for many years and have exclusively introduced the HDPE seawater cooling system to Asia. We possess multiple technical patents for HDPE marine pipe construction and continue to research and develop large-diameter products. By 2022, we have achieved a single pipe diameter of 3.5 meters.

HDPE 海管研究開發里程碑

Milestones in HDPE Marine Pipe Research and Development

水理研究專業團隊

HYDRAULIC RESEARCH PROFESSIONAL TEAM

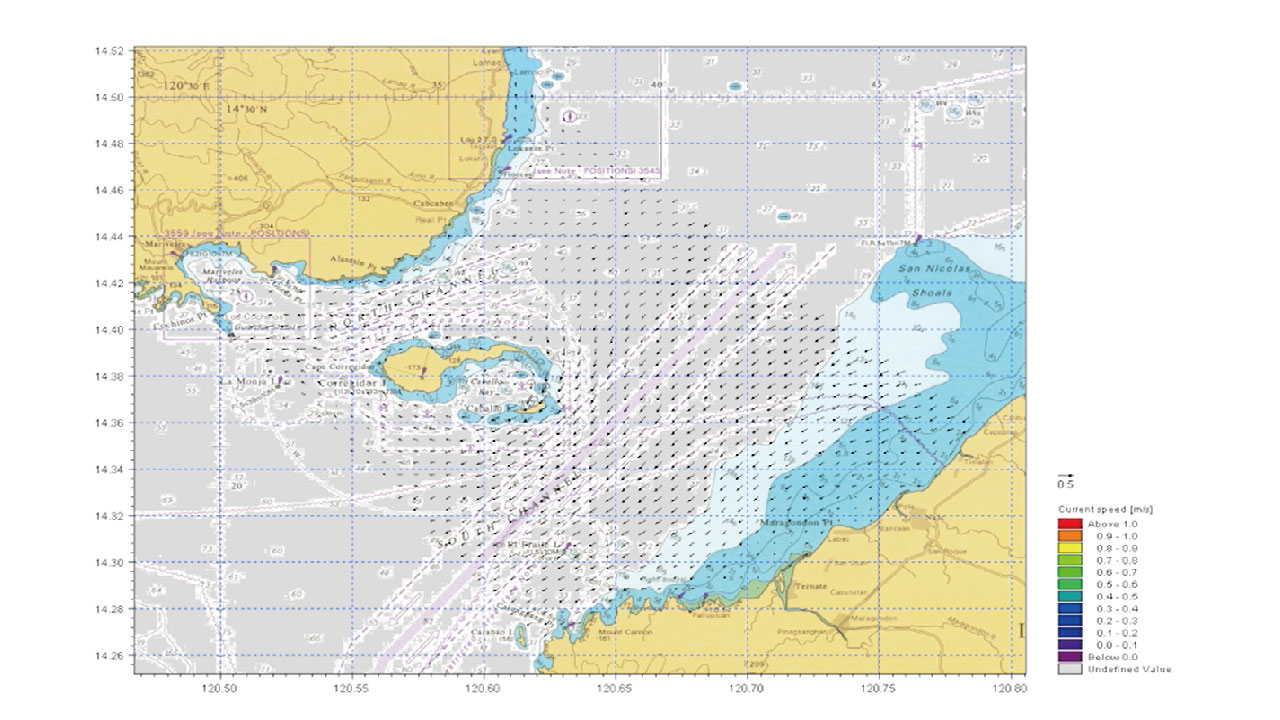

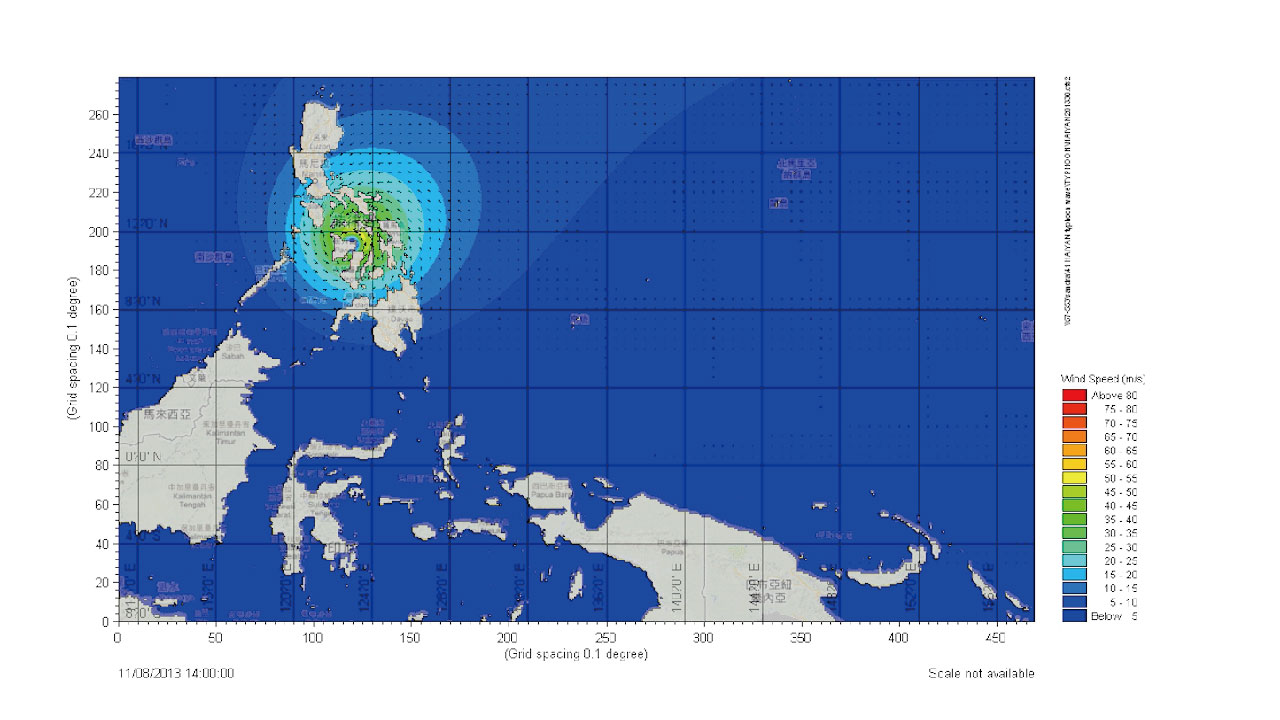

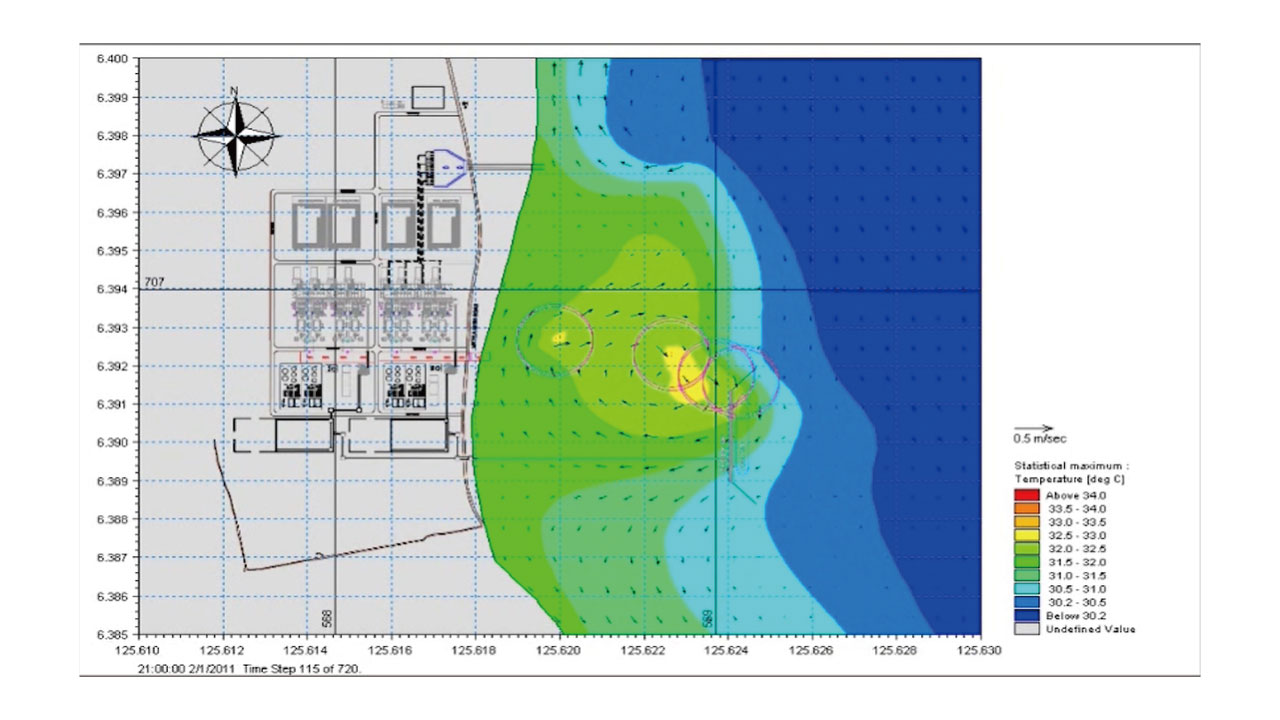

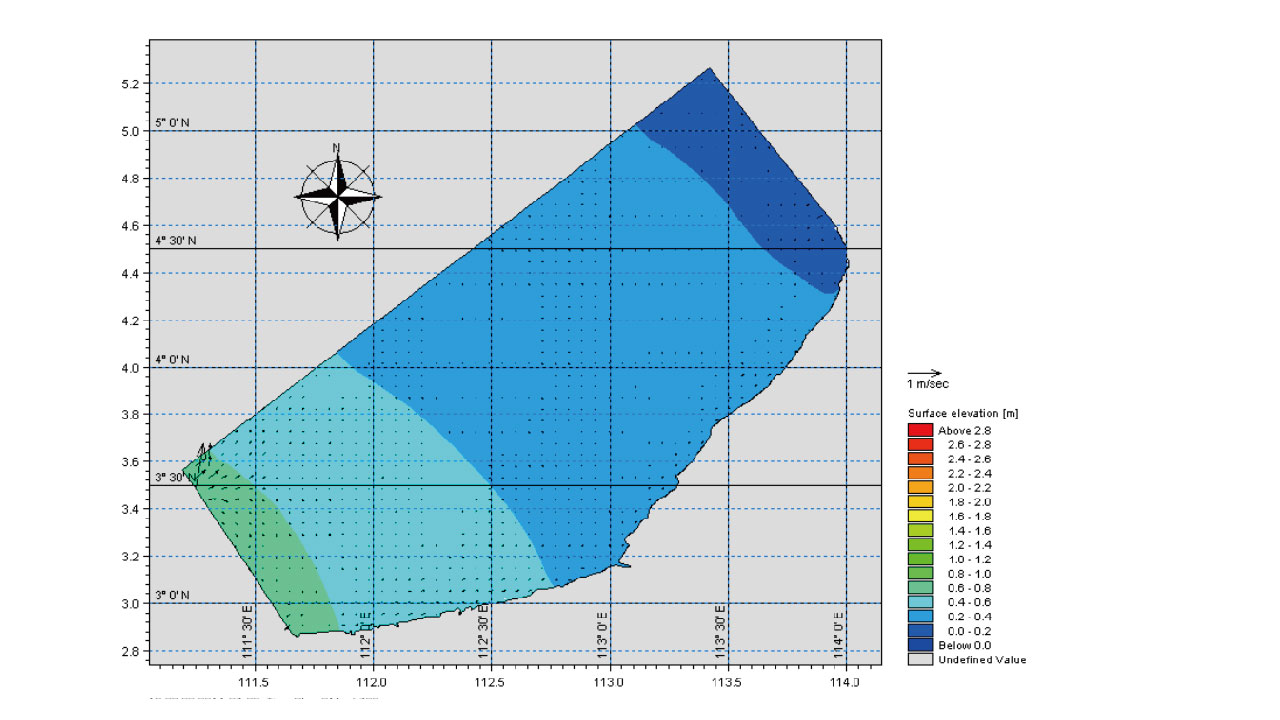

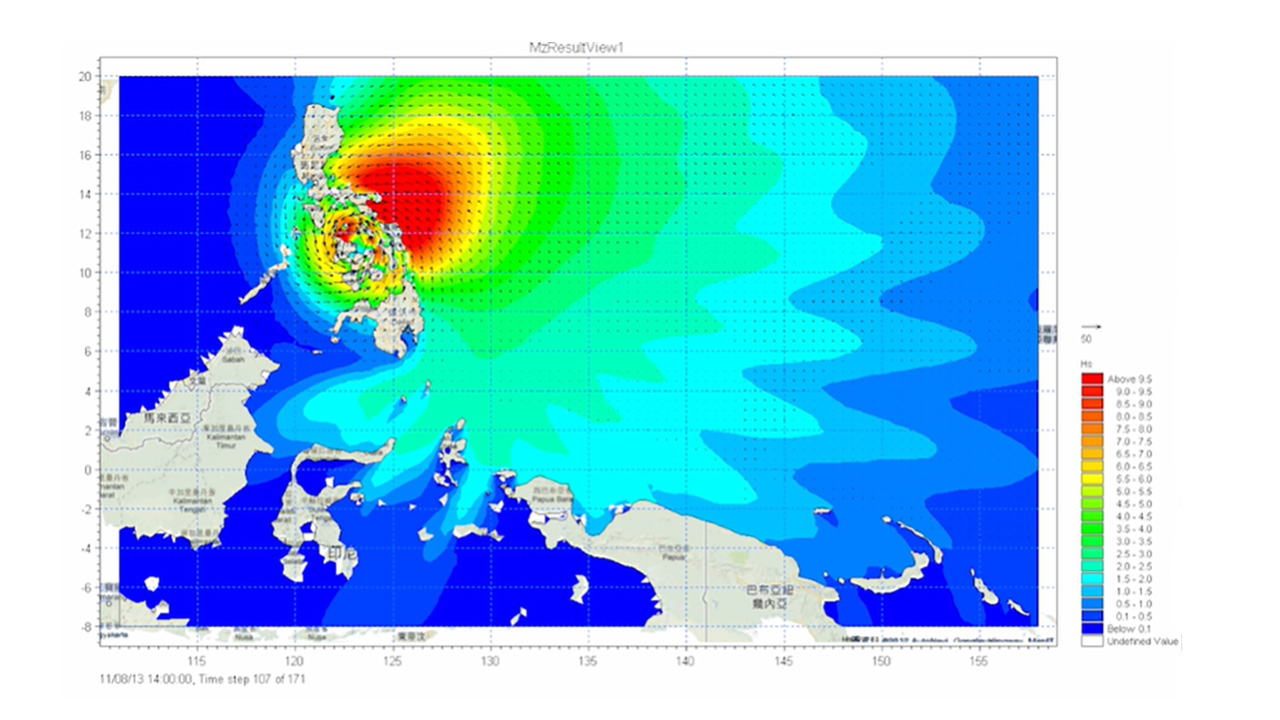

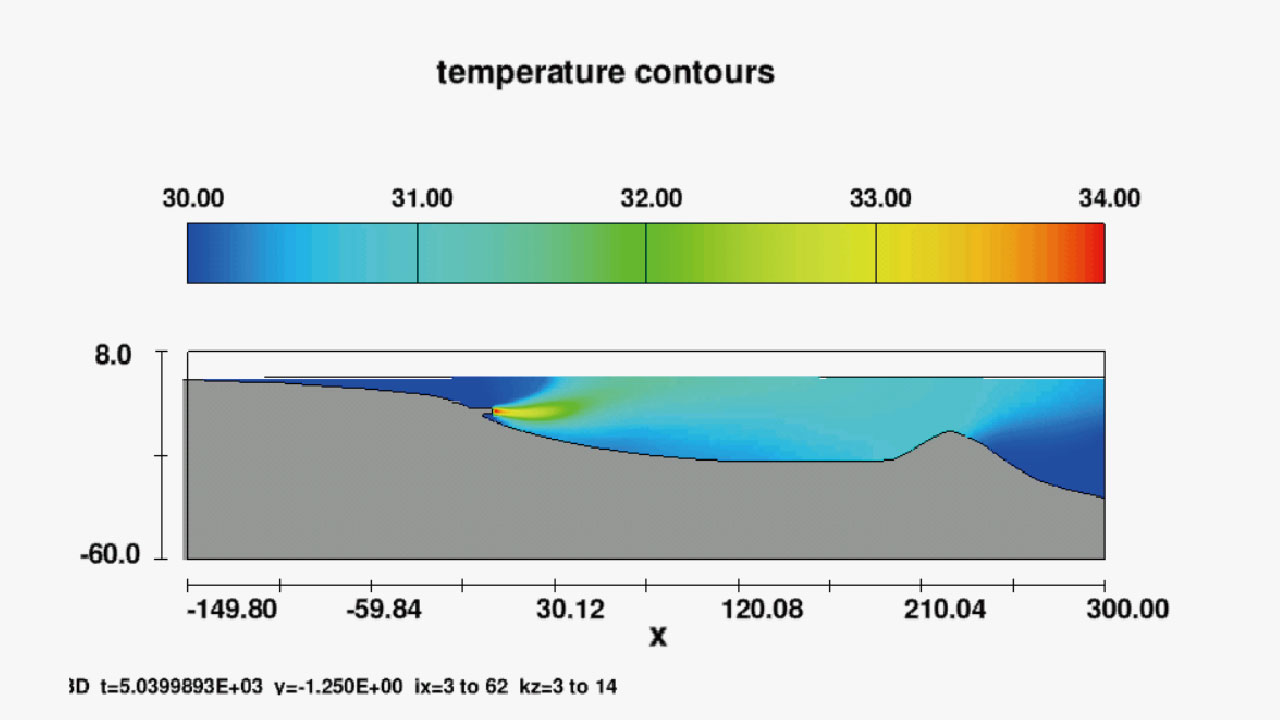

由我們的總經理龔博士帶領的水理研究室,運用高科技分析海洋模型,取得數據做為工程前期規劃,提供事業主選址建廠參考。在進行可行性評估的同時,我們先於市場掌握業務資訊,為我們取得優先承攬的機會。

The Hydraulic Research Laboratory, led by our General Manager, Dr. Gong, utilizes cutting-edge technology to analyze ocean models and obtain data for preliminary engineering planning. This data is provided as a reference for business owners in selecting locations for plant construction. While conducting feasibility assessments, we proactively gather market intelligence, enabling us to secure priority contracts.